Accenture, Mujin form robotics integration joint venture

Accenture and Mujin have created a joint venture to help bring robotics and automation to the manufacturing and logistics industries. Called Accenture Alpha Automation, the new venture is owned 70% by Accenture and 30% by Mujin.

The new company will combine Mujin’s industrial robotics expertise with Accenture’s digital engineering and manufacturing service, Industry X. Accenture Alpha Automation officially started operating on Jan. 15, 2024. It is located in Tokyo and will offer services such as consulting, conceptualization and system integration.

“Manufacturing is the cornerstone of Japanese industry. Driving sophistication and efficiency in manufacturing and the logistics that support manufacturing is essential for Japan’s further growth,” said Atsushi Egawa, who leads Accenture’s business in Japan. “By teaming with Mujin, a leader in robotics technology, Accenture will be able to help our clients take advantage of AI and robotics to connect data throughout the manufacturing and logistics value chain, further contributing to the data-driven transformation of Japan’s important manufacturing and logistics industries.”

Accenture expands integration capabilities

Accenture has historically been a strategy and consulting firm. But in recent it years it has acquired robotics integration firms to expand its business offerings. In early 2021, for example, Accenture acquired Pollux, a provider of industrial robotics and automation. This was Accenture’s first acquisition of the kind.

At the time of the deal, Pollux had implemented more than 1,000 projects for manufacturing companies, primarily in Brazil. It said it has deployed 150-plus collaborative robots successfully throughout Brazil. Accenture said many of the world’s largest pharmaceutical and food companies use technology solutions from Pollux in their Brazil operations. And a high number of vehicles made in Brazil use Pollux’s manufacturing solutions.

In 2022, Accenture acquired Eclipse Automation, a provider of custom automation and robotics solutions for manufacturing applications. Eclipse Automation creates automated manufacturing systems for life sciences, industrial equipment, automotive, energy and consumer goods companies.

Accenture partnership a win for Mujin

Japan is a robotics powerhouse. It had the fourth-highest robot density of any country in 2022, according to the International Federation of Robotics. Robot density measures the number of operational industrial robots per 10,000 employees in a country.

There are a lot of companies in Japan that Accenture could have chosen to partner with. This should be a big boost of confidence for Mujin and further legitimize its technologies.

“Our mission is to make industrial robots intelligent and easy to use so they can improve productivity and quality and help create new value in an aging society,” said Mujin CEO Issei Takino. “The new joint venture, which builds on our agreement with Accenture, will utilize our robot automation technology to drive a paradigm shift in the manufacturing and logistics industry and bring new value to customers first in Japan, then around the world.”

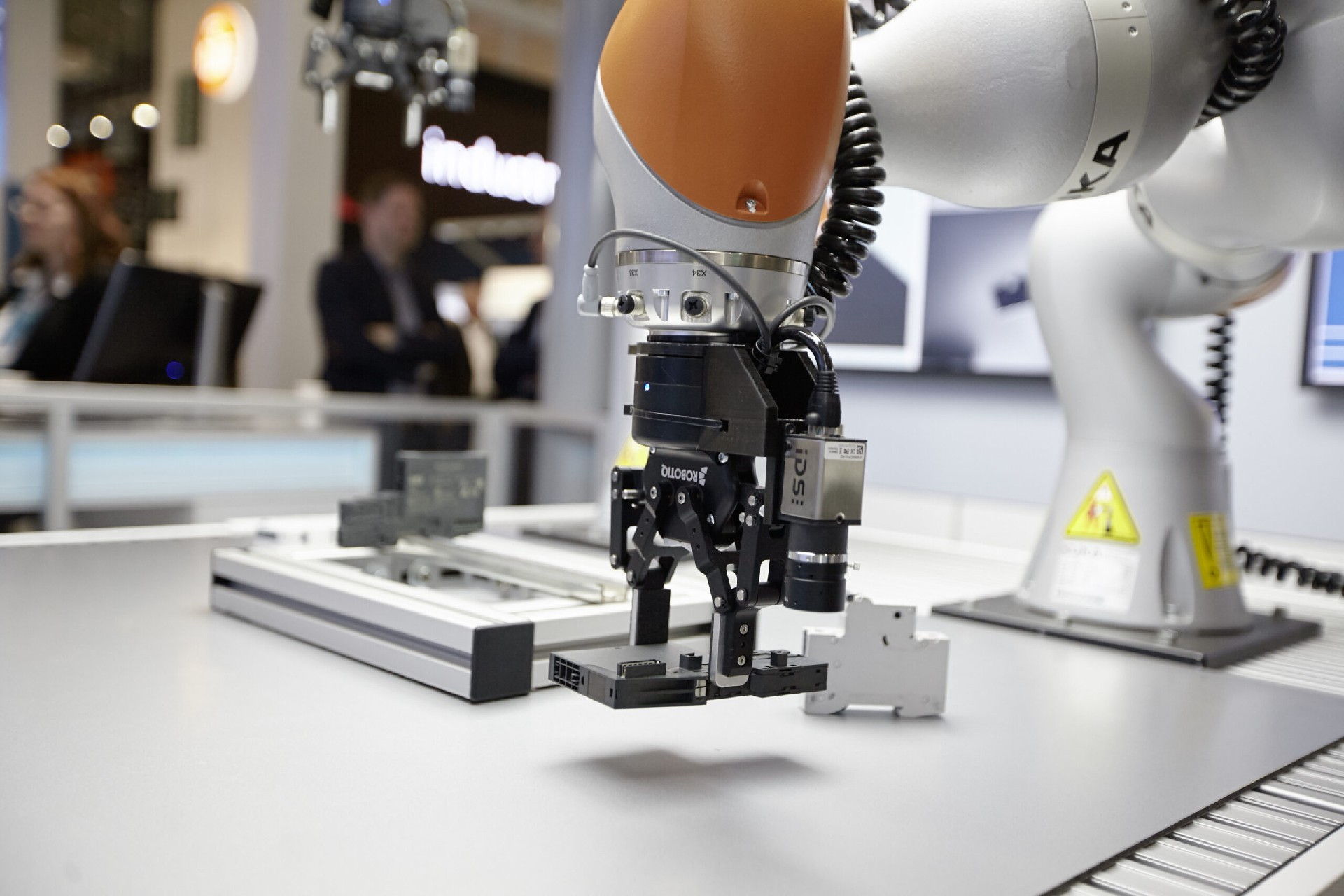

Mujin was founded in 2011 and is based in Tokyo. Mujin said it designed its controllers as a common platform for industrial and collaborative robots for pick-and-place and other logistics applications. The company said its MujinController uses “machine intelligence” and “real-time digital twins” to enable robots to operate autonomously and reliably in production.

Accenture has also invested in Mujin through Accenture Ventures. Mujin recently finalized a Series C extension round of funding with an additional $18 million, bringing its total Series C funding to $104 million. Mujin said it plans to use the funding to advance the accessibility of its MujinController platform for robotics integrators and end users. Mujin has raised a total of $178 million.

-

Analysis: What is driving Industry 4.0 momentum in APAC?

Recent research by India-based research group Mordor Intelligence found Asia-Pac···

-

Accenture, Mujin form robotics integration joint venture

Accenture and Mujin have created a joint venture to help bring robotics and auto···

-

Servo Drive System Equipped With New Hard- and Software

Siemens is innovating the well-established Sinamics S210 servo drive system with···

-

The Future is Now: AI and Factory Automation in 2024 and Beyond

In the midst of the Fourth Industrial Revolution, the future of manufacturing st···

参展地址:中国国际展览中心(朝阳馆)

- Analysis: What is driving Industry 4.0 momentum in APAC?

- Accenture, Mujin form robotics integration joint venture

- Servo Drive System Equipped With New Hard- and Software

- The Future is Now: AI and Factory Automation in 2024 and Beyond

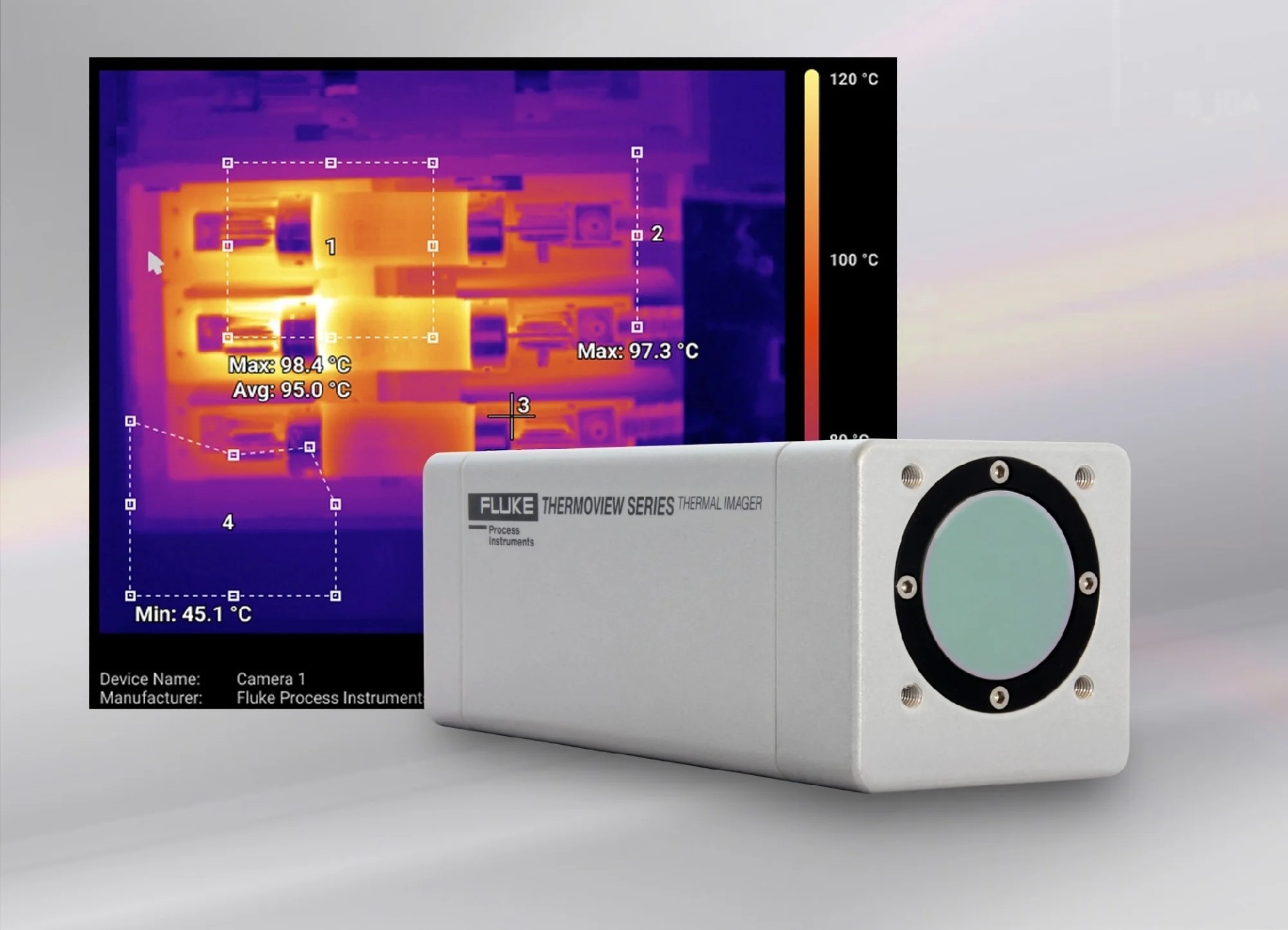

- Thermal imagers for advanced factory automation, quality assurance and process monitoring

- Industrial Operations in Asia to Adopt AI/ML for Automation Processes by 2026

Asia International Industry Automation & Intelligent Manufacturing Exhibition

Asia International Industry Automation & Intelligent Manufacturing Exhibition